Sanitary napkins are essential hygiene products used by millions of women worldwide. Understanding their raw materials and manufacturing processes provides valuable insight into product quality, safety, and performance.

The primary raw materials used in the production of sanitary napkins include nonwoven fabric, fluff pulp, super absorbent polymer (SAP), polyethylene (PE) film, tissue paper, and release paper. Each material serves a specific function within the product. Among these, fluff pulp and super absorbent polymer (SAP) are the most critical materials, as they are responsible for absorbing and retaining menstrual fluid, making them the core components of a sanitary napkin.

A sanitary napkin is typically composed of four main layers, arranged from top to bottom:

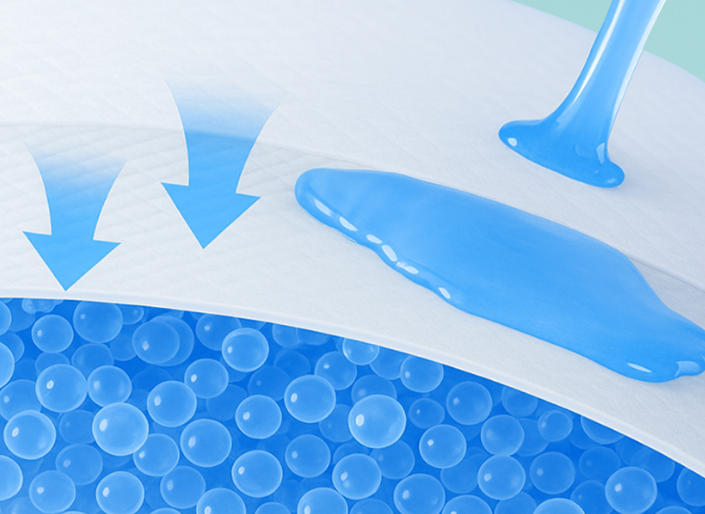

Top Sheet: This is the layer that comes into direct contact with the skin. It allows menstrual fluid to pass quickly into the inner layers of the napkin.

Absorbent Core: This layer is designed to absorb and retain menstrual fluid.

Back Sheet (Leak-Proof Layer): This bottom layer prevents fluid from leaking out of the napkin.

Together with the absorbent core enclosed inside, the sanitary napkin functions as an integrated system. Each component plays a vital role in ensuring effective absorption and leakage prevention.

Top Sheet: The top sheet is the skin-contact layer. It is typically made of nonwoven fabric or perforated film, enabling rapid liquid absorption while keeping the surface dry.

Absorbent Core: The absorbent core is the most critical part of a sanitary napkin, responsible for absorbing and locking in menstrual fluid. It is usually composed of wood pulp, super absorbent polymer (SAP), or a blend of both. SAP can absorb many times its own weight in liquid, offering exceptionally high absorbency.

Back Sheet (Leak-Proof Bottom Layer): The back sheet is the outermost layer of the sanitary napkin and is designed to prevent leakage. It is typically made from polyethylene or polypropylene film and provides waterproof protection while remaining breathable.

Release Paper: This is a protective layer that covers the adhesive before use. It is commonly made of silicone-coated paper or film.

Wings: Some sanitary napkins are equipped with wings, which are extensions of the back sheet. They fold over the sides of the underwear to enhance security and stability. Wings are usually made of nonwoven fabric or film.

The production of sanitary napkins involves multiple stages, each of which is crucial to ensuring the final product’s quality and performance. Below is an overview of the manufacturing process:

Material Preparation

Raw materials are prepared and subjected to quality inspection. The top sheet, absorbent core materials, back sheet, and other components are cut to the required dimensions.

Core Formation

The absorbent core is typically formed by combining wood pulp with super absorbent polymer.

Lamination and Assembly

The top sheet, absorbent core, and back sheet are layered and bonded together, followed by the addition of release paper. If the sanitary napkin includes wings, they are added at this stage.

Cutting and Shaping

Precision cutting equipment is used to cut the assembled layers into individual sanitary napkin shapes. The edges are sealed to prevent fraying and to ensure durability.

Packaging

The finished sanitary napkins are sealed in hygienic packaging to maintain cleanliness and safety. They are then packed into cartons for distribution.

Quality Control

Quality control inspections are conducted throughout the production process to ensure the sanitary napkins meet safety and performance standards. These tests include absorbency, leakage prevention, and skin irritation assessments.

In summary, B.I. Healthcare sanitary napkins are designed to deliver comfort, high absorbency, and reliable protection.

*BI-Ehealthcare makes no warranties or representations regarding the completeness or accuracy of the information. This information should be used only as a guide and should not be relied upon as a substitute for professional medical or other health professional advice.